Solaris midstream is an independent growth oriented midstream company headquartered in houston texas that owns operates and designs crucial midstream assets across key unconventional u s.

Flowback water treatment companies.

A recent installation of opus ii technology in southern california integrates the ceramic membrane system as pretreatment prior to ion exchange and reverse osmosis.

The ross system is a critical part of other produced water treatment systems offered by veolia water.

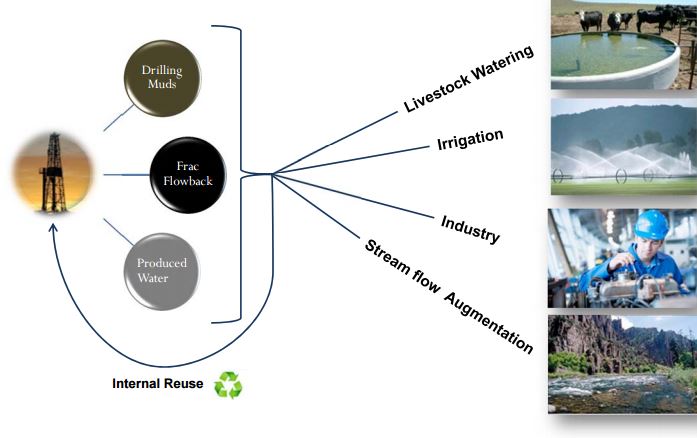

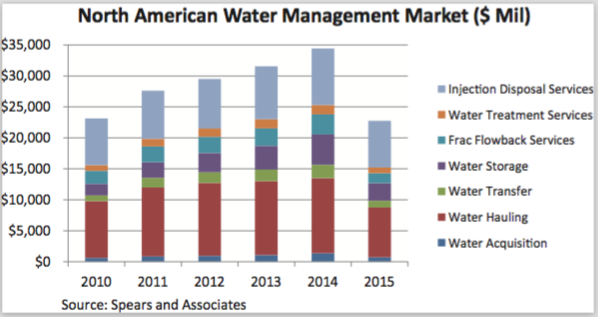

With the ratio of water to oil ranging from 3 1 to 11 1 a readily available alternative resource is flowback and produced water.

We offer a full line of flowback equipment and flowback rentals including sand separators plug catchers test units and flow tanks.

Systemized chlorine dioxide clo 2 on the fly mobile treatment of produced and flowback water in tanks pits and ponds.

Solaris is initially focused on developing cost effective efficient and reliable water specific midstream solutions.

Hydrozonix water treatment technology uses mobile and permanent systems that are ozone based and require no liquid chemicals as well as portable aeration systems that maintain the quality of stored flowback and produced water.

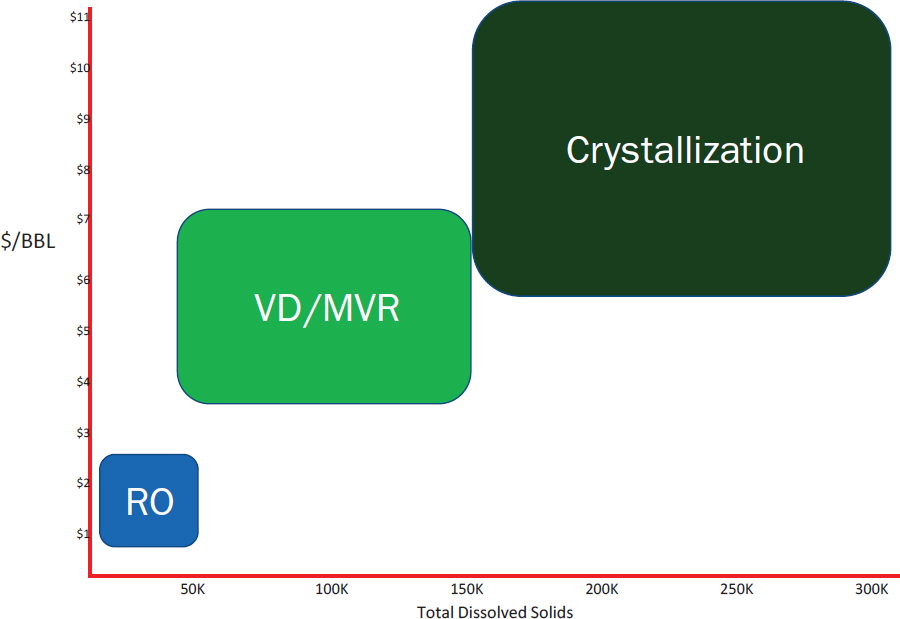

When deciding between water treatment methods to treat flowback and produced waters it is important to consider the end use and its specific requirements as well as composition of the water.

Flowback is necessary for initial well cleanup to remove fluids that were introduced to the well and any debris that accumulated in the wellbore.

Our mobile miox frac water unit offers an efficient effective low cost solution for treating high volumes and high rates of flowback water with superior bacterial kill.

The company provides advanced technologies separately or as part of its hzo trio program which can replace.

Knowledge of the fracture fluid employed is required when considering the recycling methodology in order to identify the required treatment characteristics.

Full line of flowback equipment.

This project is designed to produce 45 000 barrels per day bpd of high quality effluent.

Sand separators used by select protect testing and production equipment during the flowback process and effectively remove sand debris from frac tanks saving on cleanup costs.

Treatment requirements for flowback and produced water are normally established by the company performing the well completion.

And because miox technology operates with salt water and electricity there are virtually no health safety or environmental concerns at the drill site or down hole.

As part of a our h 2 o spectrum platform water standard is helping energy companies lower operating costs by safely and economically treating their flowback and produced water using our most compact and modular h.

The produced fluids are collected for recycling or disposal.